Industry news

Your current location:Home> News

KIMS developed the world's best performance rare earth permanent magnet

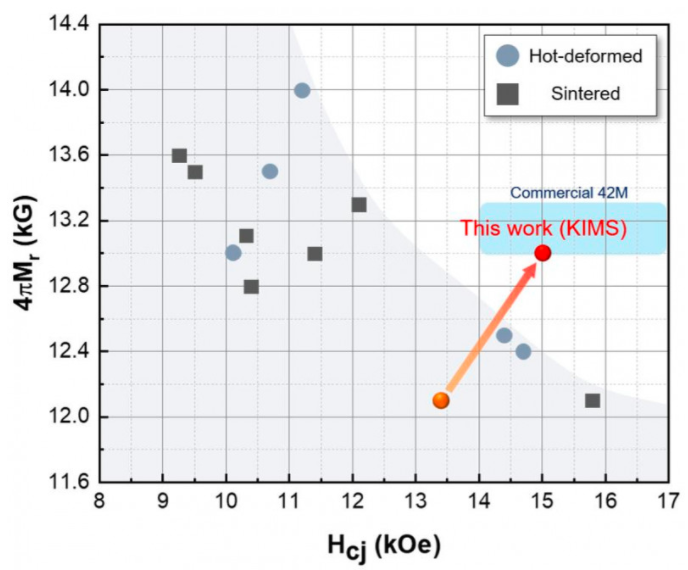

Dr. Lee Jeong Gu and Dr. Kim Tae Hoon from the magnetic materials department of the powder materials department of the Korean Institute of materials science, a state-owned research institution under the Ministry of science, technology and information communications, have successfully developed a "rare earth reduced permanent magnet" which can achieve the performance of commercial magnets (grade 42) and reduce the content of expensive rare earth neodymium (nd) by about 30%. Although this technology reduces the amount of high priced rare earths, it reaches the level of commercial magnets currently used in industry and has important value.

Neodymium (nd) is expensive and its supply is unstable, but it has been inevitably used because it is a necessary material for manufacturing rare earth permanent magnets. In order to develop neodymium reducing permanent magnets, the content of cerium (CE) must be increased to replace the reduced content of neodymium (nd). Cerium is a cheap element. With the increase of cerium (CE) content, the deterioration of magnetic properties can not be prevented until now. The research team focused on elucidating the causes and mechanisms of the deterioration of magnetic properties caused by the increase of cerium (CE) content, and successfully solved the problem of rare earth decrement permanent magnet by controlling the atomic scale microstructure

Researchers found that unnecessary magnetic particles were formed in the existing manufacturing process, which was the reason for the deterioration of the microstructure and magnetic properties of the magnet. They improve the microstructure of the magnet, enhance the magnetism, and prevent the formation of unnecessary magnetic particles by inhibiting the diffusion of atoms in the magnet.

The research team applied the fuse spinning method and thermal deformation method, which have a faster cooling rate than the traditional process, to the manufacturing process of rare earth reduction precursor and permanent magnet respectively. As a result, they successfully optimized the microstructure of the magnet by suppressing the formation of unnecessary magnetic particles. In addition, they can also improve the main properties of permanent magnets - remanence and coercivity. Because the remanence and coercivity are a balance relationship, the technology to improve these two main properties is very useful and valuable.

Dr. Jin taixun, the leader of the research group and chief researcher of the Central Research Institute, said: "if this technology is commercialized, it will solve the resource problems and the problems of materials, parts and equipment in the domestic rare earth permanent magnet material market at the same time." This is just the beginning. Through further research in the future, we will spare no effort to lead the development of the domestic rare earth permanent magnet industry. "

This research is supported by the basic research project "technical development project of magnetic powder materials with improved composite magnetic structure" of the Chinese Academy of Sciences and the Ministry of science and technology. In addition, the research results were published in scripta materialia, the world's top 5 academic journal in the field of metal materials, on March 17 (the first author gayoung Kim, Ph.D., Title: high performance CE generation) (nd0.7ce0.3) - Fe-B thermal deformation magnet, prepared from amorphous melt spinning powder).

For more info see: www.kims.re.kr/