products

Your current location:Home> product

Ferrite Magnet

-

Current Price:

MOQ:

Total supply:

Ship Date:

Overview:

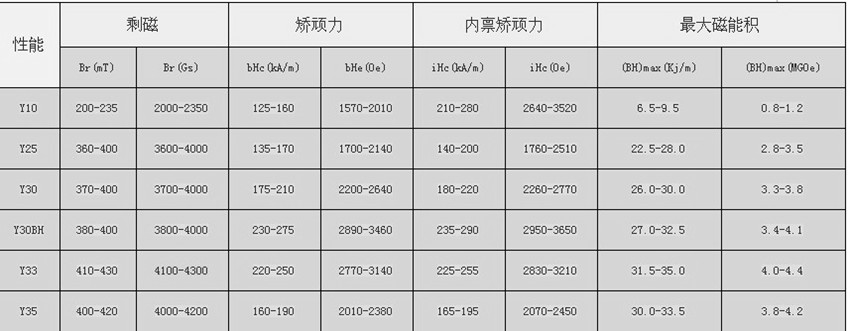

Permanent magnetic ferrite is also known as hard ferrite, which is a non-metallic magnetic material. In 1930,Kato and Takei discovered a kind of permanent magnet with spinel (MgA12O4) structure, whcih was the prototype of today's widely used ferrite.The main raw materials of ferrite product are SrO or BaO and Fe2O3.Ferrite is produced by the ceramic process “pre-burn, crushing, milling, pressing, sintering and grinding”,with the features of wide hysteresis loop, high coercivity, high remanence,and it can maintain a constant magnetism after magnetization and its density is 4.8g/cm3.According to different production processes, it is divided into two kinds,sintered and bonded ferrite magnet,while the sintering ferrite is divided into wet and dry pressing molding,and bonded ferrite includes extrusion molding, compression molding and injection molding.The bonded ferrite powder and synthetic rubber also can be used to make soft, flexible and twistable rubber magnet.Based on whether adding magnetic field when forming,it is divided into isotropic and anisotropic permanent magnet.

Compared with other permanent magnet materials:

Advantages: cheap, broad raw materials source,high resistance to high temperature (250 degrees maximum) and corrosion.

Disadvantages: low remanence compared with NdFeB products,in addition, because of its relatively low density, loose and friable material structure,many processing methods are subject to its limitations,such as drilling, digging holes. Most of its products only can be made through the molding with poor product tolerance accuracy and high tooling cost.

Coating: because of its excellent corrosion resistance, there is no need to add the coating.