products

Your current location:Home> product

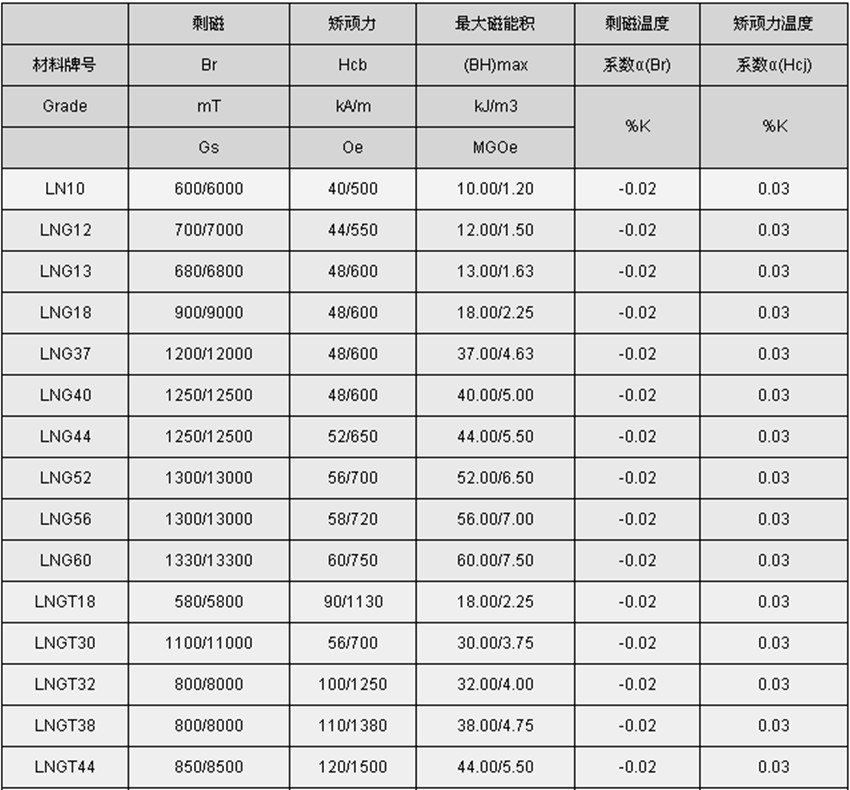

AlNiCo Magnet

Overview:

AlNiCo was the earliest permanent magnet material, which is an alloy made of aluminum, nickel, cobalt, iron and other trace metal elements. Alnico materials are successfully developed in 1930s. At that time, it had the best magnetic properties and small temperature coefficient; as a result, it was widely used in the permanent magnet motors.In 1960s,with the advent of ferrite magnet and rare earth permanent magnet, AlNiCo magnet’s application in the motor was gradually been replaced, the proportion also was declined.Because of different production process,it includes Sintered AlNiCo and Cast AlNiCo. Casting process can make out products with different sizes and shapes, compared with casting process, sintered process only can produce small size sintered product. The tolerance of sintered processed blanks is better than that of cast processed products, while the magnetic property is Slightly lower.but with better workability

Compared with other permanent magnet materials:

Advantages: Alnico’s biggest advantage is its high temperature stability, in our experiments, in 600 degree heat environment, remanence remains unchanged. Therefore, it gets irreplaceable position in the field of instrumentation application. In addition, as it can be produced by casting,the product shapes have more choices. Furthermore its corrosion resistance performance is also excellent.

Disadvantages: Alnico’s biggest drawback is the low coercivity,the product can be easily demagnetized by reverse magnetic field. That’s the fundamental reason why it is not widely used .