products

Your current location:Home> product

Bonded NdFeB Magnet

Overview:

The advent of bonded magnets is around in the 1970s,when the SmCo magnet has reached commercialization.While the market of sintered permanent magnet is in good condition,but sintered magnet can hardly be processed into special shapes,for in the production process,cracking,breakage and other problems easily occur.Besides,it is difficult to assemble.All these drawback limits its wide application.To solve this problem, pulverizing the permanent magnet and mixed them with plastics,and then get them into compression molding in a magnetic field,that’s probably the most primitive bonded magnet manufacturing method.

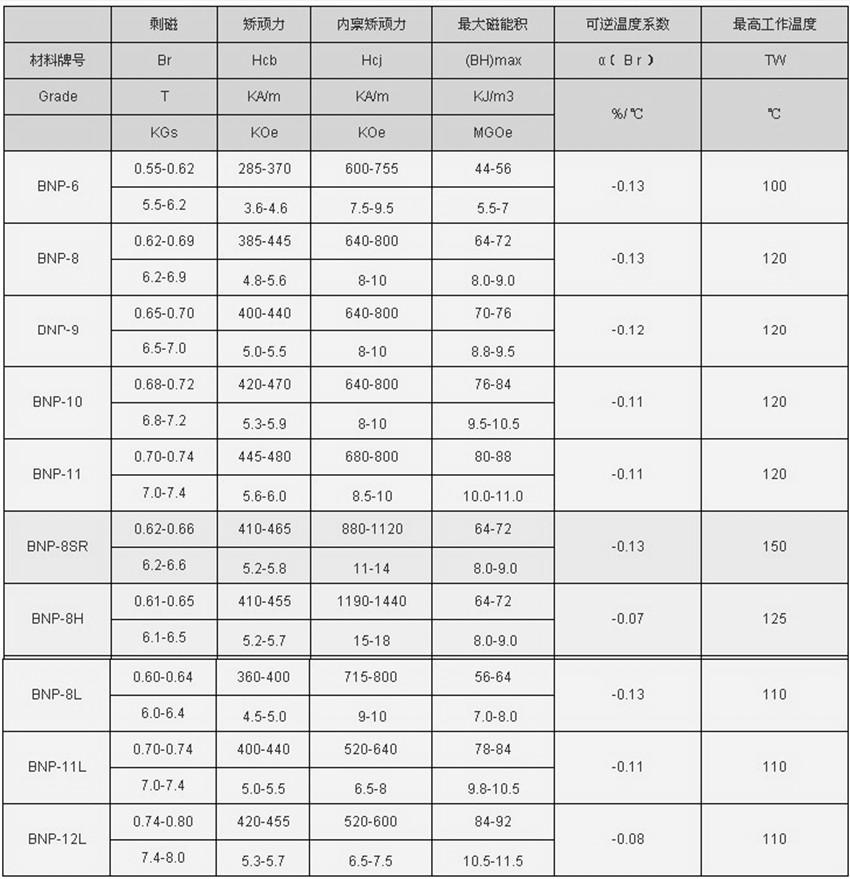

Bonded NdFeB is molded by NdFeB alloy powder with epoxy resin by pressing,or mixed with plastics by injection molding or extrusion molding.

Compared with other permanent magnet materials:

Advantages: low cost,high dimensional accuracy,more shape choice,good mechanical strength,light weight.

Disadvantages:due to a large number of non-metallic materials (plastics, adhesives, etc.) is mixed into the magnet powder,its performance is generally low,the maximum working temperature of the products is also limited(usually about 120℃). In addition,most of the products require mold production,which will undoubtedly increase the R & D costs in the early development stage.